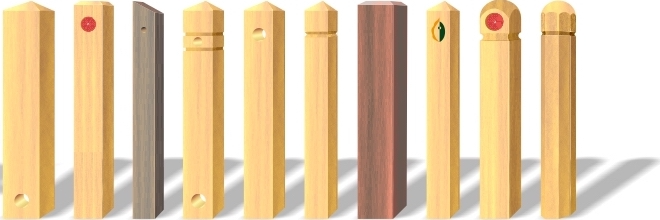

Types of Timber Bollards

Crafting High-quality Bollards

We can supply bollards up to 300mm square and 3.0 meters long. The timbers we supply are Cypress pine, unseasoned SpottedGum and Iron Bark. The most used timber for bollards is CYPRESS PINE, due to its class 2 below ground rating, low shrinkage rate of 2.9% and its natural resistance to white ants.

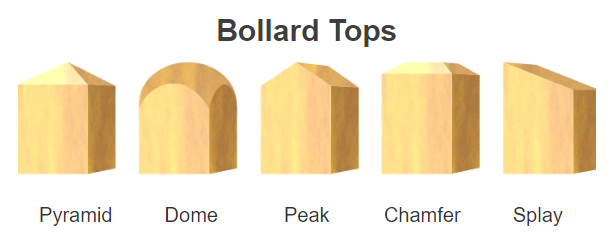

Bollard tops can be made in many different shapes and sizes. The size of a chamfered top is most commonly 20mm and a pyramid top is set at 35deg, but this is only a guide. We can manufacture your bollard tops to almost anyshape and size, to meet your specifications.

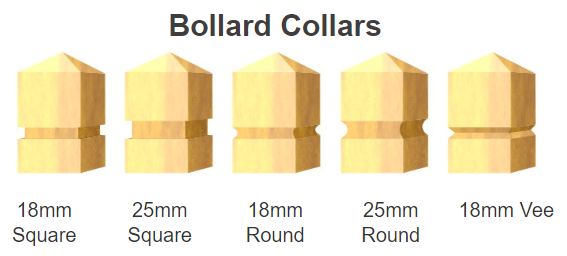

Collar sizes vary from job to job, the same as the bollard tops. We have manufactured them from 4mm to 110mmwide and up to 25mm deep, but the most common size is 18mm wide by 10mm deep and the most common shape is square. Because each job is unique, we have the experience to help you create any shape you require.

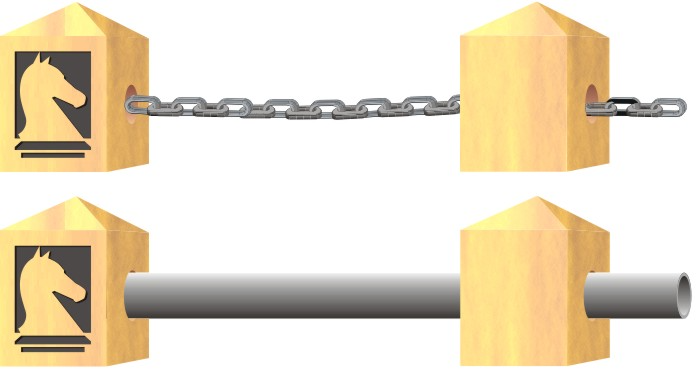

Chain, Pipe & Cable Holes

We can drill your Chain, pipe or cable holes up to 85mm. Through bollards up to 300mm square or round. We recommend the hole size for pipe, be 5mm bigger than the outside diameter of the pipe required and 4mm bigger for chain and cable.

Bollard Extras

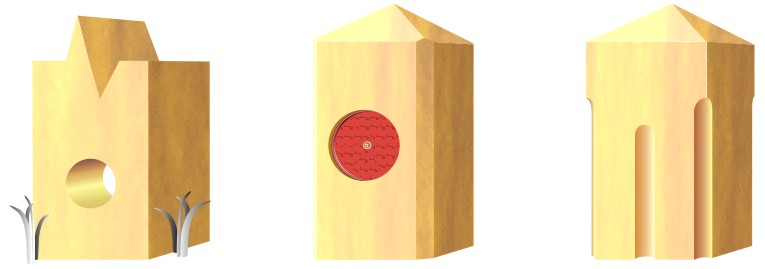

Impact protection holes are widely used in bollards along roadsides parks and reserves to lessen the impact of a vehicle collision. They are usually accompanied by delineators recessed 10mm into the bollards to prevent vandalism. Red delineators on the approach side and white the opposite side.

Where scalloped edges are more for decorative purposes. Chamfering the edges of a bollard, also makes a bollard more user friendly by alleviating sharp corners and splinters.

Installation Guide

If you are planning to tackle a fencing or bollard project on your own, please download our guidelines at our resources page.

FAQ's

We recommend using premix concrete, either delivered in a mini mix or by making your own ready-mixed or rapid set concrete in a wheelbarrow. It’s advisable to start with a small, dryer mix to set the posts’ height and line before adding the remainder of the concrete.

Leaning the posts back allows you to ensure they are at the correct height and level before adding the remainder of the concrete. This step is crucial to achieving proper alignment and stability.

Yes, Timber Bollards are versatile and can be installed in various soil conditions. However, proper installation techniques, such as using an appropriate concrete mix, are essential for stability.

The Crossing Posts are installed with a 600mm in-ground depth, leaving 1200mm out of the ground for the 1800mm posts and 1800mm above ground for the 2400mm posts. This ensures stability and visibility.

While Timber Bollards are designed for durability, removal and reinstallation are possible with proper techniques. Contact our team for guidance on temporary installations.

Book a call

Whether you’re a hands-on DIY enthusiast or prefer the expertise of professional installation, Barlings has got you covered. Our offerings include comprehensive installation guides for those who want to take on the project themselves. Additionally, for a seamless and hassle-free experience, we can connect you with trusted local installers.

Opt for Barlings for solutions that not only meet but surpass your expectations. Our range includes bollards, bollard sleeves, crossing posts, and more, ensuring a versatile selection..